Description

NEW for 2024 - Please read as the ordering for this item is now different.

Warning, if you do not read and just click order, you will receive a harness with Delphi connections. You must select Deutsch or DIN connections and then order if that is what you need.

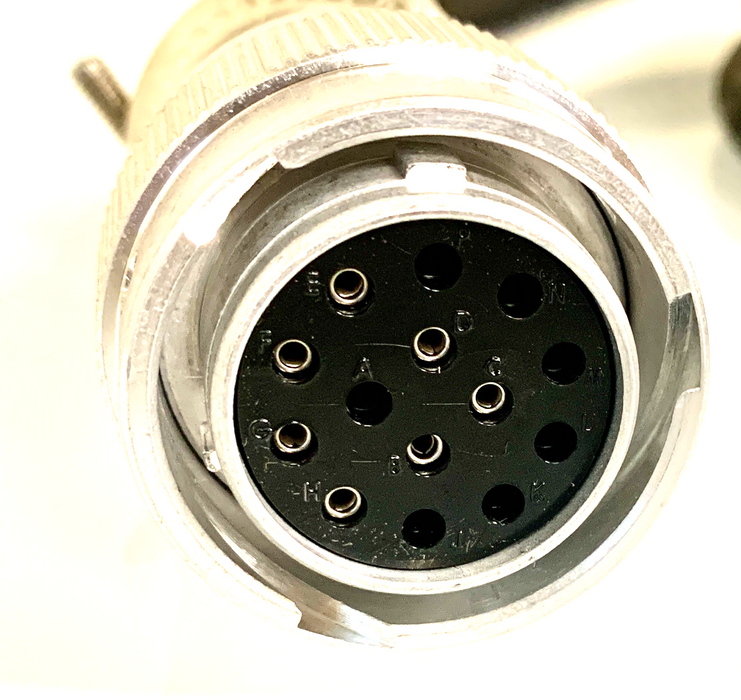

We have tried several different methods for ordering this item but we are now settling on having three distinct versions. All of the versions feature a 9 foot cable with a Deutsch 14 pin connector installed which is pinned for the common Bobcat layout which covers Case, Gehl, Kubota*, JCB/Volvo, Mustang, Takeuchi, New Holland, John Deere, Yanmar, Cat after 2014) & Wacker to your Bobcat® as well as Erskine & Quick Attach branded attachments. Inside the connector is a spare jumper from ground which allows you to push the socket into place for Cat D series High Flow or for older Bobcat pump control. What is different are the 6 connectors on the end. Bobcat, Erskine and others use different connectors on their solenoids. The invasion of Chinese attachments through RB Auctions has flooded the market with attachments requiring DIN connections.

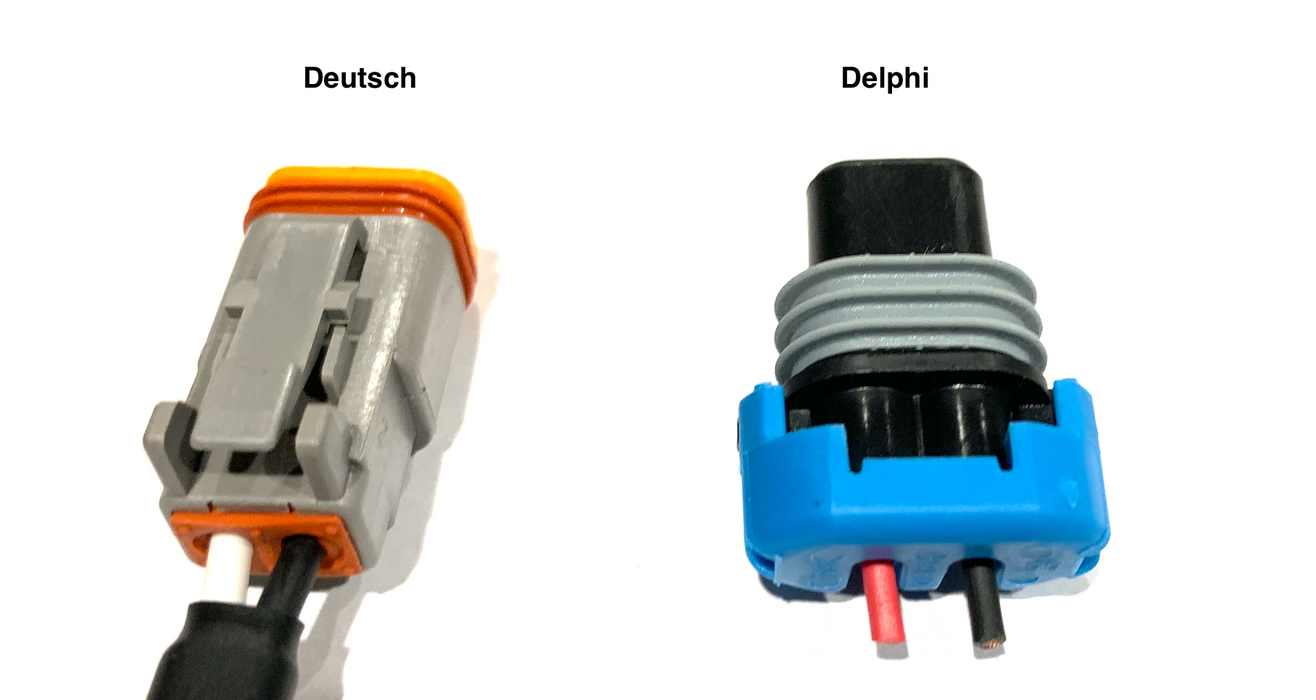

Version #1 - SG-BPH-14-6-9DP - Delphi connectors - These are easy to spot because there will be a jumper coming from the solenoid and the mating connector will have a blue cap. See photo for verification.

Version #2 - SG-BPH-14-6-9DT - Deutsch connectors - These are easy to spot because there will be a connection molded into the solenoid with a square appearance. The plug will be black or grey with an orange or green tip. See photo for verification.

Version #3 - SG-BPH-14-6-9DN - DIN connectors - These are easy to spot because there will be a square box on the end of each wire. See photo for verification.

7 Pin Bypass Harness (6 Output Delphi) For Bobcat®, Erskine and Quick Attach Branded Attachments

Connect from your Case, Gehl, Kubota*, JCB/Volvo, Mustang, Takeuchi, New Holland, John Deere, Yanmar, Cat after 2014) & Wacker to your Bobcat® as well as Erskine & Quick Attach branded attachments.We started as attachment manufacturers and felt that the 7 pin option was only designed to block users from running their attachments on anything but Bobcat® brands. There are so many hostile customers out there that we felt that we could help, so here is the deal. We built one of these to see if it would work. Our customer was more than happy to help out with feedback of how he used the harness. We posted this to our database so we could help the next guy. He posted the results to an online forum and then our phones starting ringing off the hook. So we now operate Skid Steer Genius as an example of how to actually help people and not hinder them.

This product now comes completely assembled for the old Bobcat standard pin configuration which covers Case, Kubota, New Holland, Gehl, Yanmar, Mustang. You will need to to make the following changes if you own a Cat D-series or a John Deere machine.

Cat D-Series - Pin G moves to Pin A. Pin H moves to Pin J - That's it!

John Deere - Pin B moves to Pin A. A smart thing to do would be to change the machine so it will be compatible with all attachments. Otherwise you will always changing the attachments over to match the machine. Starting in 2020 the harness has a jumper tucked inside the 14 pin connector. Open the connector, strip off the shrink tubing and install the socket into position A. You will then have a ground in position A & B which will work fine for most applications except Cat D-Series.

Click here for a video on how to move the sockets.

We ship this kit with a diagram and installation instructions so that you can pin it for your specific application. All of the pins are professionally crimped. Also included is the pin removal tool so you can move pins easily.

We have now shipped thousands of these and have a very extensive database on how and where these will work. When you buy a harness from us, the cost includes unlimited support until you get it working to your 100% satisfaction. A few of our competitors have bought these from us, copied them and now offer a similar looking item, but they have no idea how they are installed or work in all circumstances. We do

How Does it Work?

Bobcat® branded attachments that have a 7 pin harness installed have a computer installed on the attachments. We run our harnesses directly to the solenoids on the attachments from your skid steer loader. Bobcat® installs a computer right in the middle of the action. In most cases it is total overkill and not needed. They have only a few attachments that have a lot of functions that need more than the usual 8 or 14 pin outputs on every other brand in the market. In our opinion, it has more to to with marketing. They are under the mistaken thought that you will only ever buy Bobcat branded attachments. Instead, it just costs you a lot of money changing them back to the way that every other manufacturer does it.

Our harness bypasses their computer and plugs directly into the solenoids and brings the attachment back to modern reality. The other end plugs into your 14 pin harness on your machine. The only issue we have seen is if your machine is not wired for enough outputs to run that particular attachment. Example. Kubota SVL75 & SVL90, SVL95 (2016 and prior) loaders only have two outputs. This will work OK on items like brooms, but not much more. Not sure why they did not think ahead an allow for more outputs, but that is just the reality. As of June 2014 Kubota added an add on button controller to allow more controls. Check out the Genius Super Controllers for an easier installation at 1/3 of the cost.

Bobcat® Cold Planers: These attachments have sometimes have 7 solenoids. 6 are for control and one diverts the flow from the drum to the controls. If you do not have 7 solenoids, then this harness will work. If you have 7 solenoids, click here. Most skid steer loaders have 6 switches for control so they do not have enough to operate the Cold Planer the way you normally would think.

| Button 1 | Button 2 | Button 3 | Button 4 | Button 5 | Button 6 |

| Left Skid | Right Skid | Angle | Side Shift | Forward | Reverse |

This harness allows for the control of 6 solenoids. On Bobcat® attachments, this does not necessarily mean 6 functions. They often use two solenoids for each function so we rely on you to check this out prior to ordering or check our published results to see if we have already done it.

VIDEOS:

CLICK HERE FOR OUR PRODUCT INTRODUCTION

CLICK HERE FOR AN SG60 INSTALL OF THIS HARNESS

CLICK HERE FOR BOBCAT PLANER INSTALL

CLICK HERE FOR BOBCAT DOZER INSTALL

CLICK HERE FOR BOBCAT TREE SPADE INSTALL

CLICK HERE FOR BOBCAT BACKHOE INSTALL

Now the disclaimer. The "Bobcat®" trademark and logo are registered trademarks of Bobcat® Company.

This is not a Bobcat® product. We are not affiliated with Bobcat. We have not copied anything from Bobcat. We are not in any way trying to make you think you are buying a product from Bobcat® nor are we trying to make you think you buying a product endorsed by them. We expect them to tell you the same thing. After over 20 years of designing, manufacturing and selling some pretty incredible skid steer products, we know what we are doing. We stand behind this product 100% and guarantee it will not affect the operation of your machine or your attachment. It simply bypasses the common language CanBus computer on the attachment and plugs directly into the control solenoids. It does not interact with the machine in any way. We believe this to be a much more reliable way of operating an attachment. Fewer components always means less down time.